Yemoja, Ltd., a marine ingredient start-up, announces developing a red microalgae discovery for medium-rare plant-based burgers and steaks that adds authentic “bloody” juiciness.

Branded Ounje, meaning “Food” in the Yoruba language, this formulation mimics the red juices of real meat without harming animals or the planet and without the need for artificial colour additives.

The company discovered that this marine ingredient, when combined with other derivatives from this same Porphyridium strain of algae, can provide a nutrient packed medium for rendering the sensory characteristics of juicy meats for plant-based meat and cultured meat products.

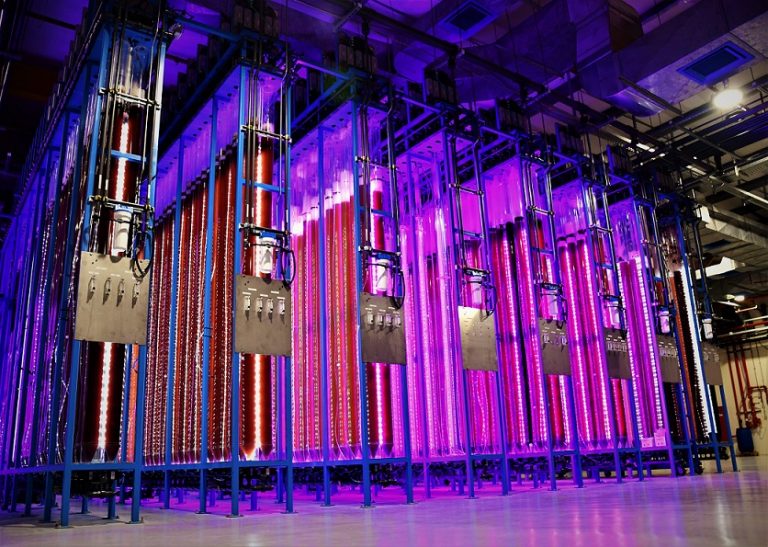

Yemoja operates a cutting-edge, indoor system for cultivating high-value, pure, and standardized microalgae bio compounds serving the nutraceutical and cosmetics B2B sectors.

The platform system allows the manipulation of light, temperature, and pH to yield high concentrations of desired bioactive compounds with minimal ecologic footprint and without contaminants, using minimal resources, and sharply reducing waste.

The deep red algae is grown indoors in high precision, photobioreactors and exhibits potential to act as a natural, clean, and 100% plant-sourced heme substitute to serve the cultured meats and plant-based alt meat sectors.

“While working on a new formulation for cosmetic applications, we serendipitously discovered that this specific composition yields a substance that resembles blood in appearance and texture,” notes Amikam Bar-Gil, PhD, co-founder and CTO of Yemoja. “Encouraged by the first test results, we decided to push the boundaries further and take it to the next level, trying it out in test products. The results were an immediate proof of concept.”

When it comes to creating plant-based meats and hybrids, there is a strong demand for a convincing blood-substitute to award the growing pool of ethically conscious diners the full experience of biting into a juicy beef burger. This niche is currently witnessing a wide use of beetroot juice and other colour additives.

These various additives help accord the desired colour effect at its raw stage but still cannot change colour in the manner that meat does when cooked. This often necessitates adding various sugars that caramelize when heated to attain the desired effect.

In a technological leap forward, Yemoja’s patented microalgal heme substitute not only provides the initial red pigment to raw plant-based meats, but it also browns up nicely when put to the sizzle.

Moreover, it also congeals like real meat juices. “We found the polysaccharides within this particular algae species express a viscosity similar to gelatin when cooked. Its natural fiber also awards an appealing crunchiness and emits an appetizing meaty aroma.”

Beyond the visual and textural meat-like appeal that the algae provides, it also gives an added nutrient boost to the product. Microalgae is a highly sustainable crop boasting a 20%-30% protein load and harbours the complete essential amino acids profile. Algae are also a valuable source of essential fatty acids, polyphenols as well as minerals and vitamins, and gaining esteem as a powerful superfood.

“The demand for clean, naturally sourced alternative proteins that can dually exert a less harmful impact on the environment is an internationally sought venture,” contributes Erez Ashkenazi, co-founder and CEO of Yemoja. “Our advanced patented cultivation system offers a high-value yet cost-effective solution that can be easily scaled up to the unique needs of the various alt protein/meat producers to help bolster this rapidly growing category.”

Yemoja produces its algae heme substitute via a cold process in its GMP-certified facility without using any organic solvents. “We believe our algae can imbue cultured meat-cells with a nutrient-rich media to feed on. We are currently assessing its potential to act as a suitable biomaterial scaffold on which the cells can grow.

“This structure will allow it to mimic the behavior of meat, especially when it hits the skillet,” notes Bar-Gil. He adds that the ingredient can make up to 10% of the end product.

The start-up currently is piloting its microalgae ingredient with one plant-based start-up and another cultured meat producer. Reported results so far have been highly promising